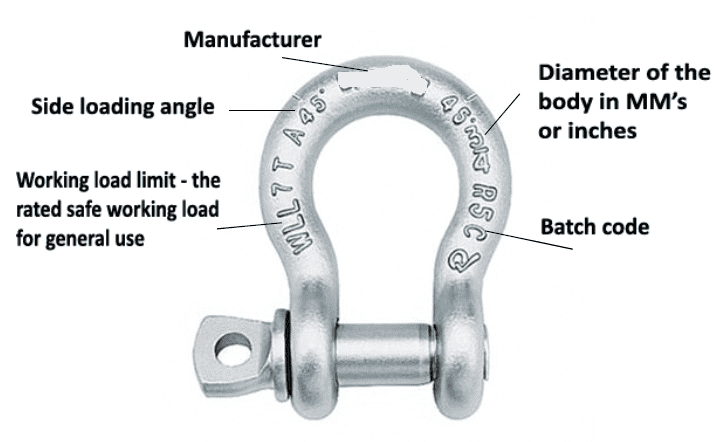

WORKING LOAD LIMIT (WLL)

The Working Load Limit is the maximum load which should ever be applied to the product, even when the product is new and when the load is uniformly applied -straight line pull only. AVOID SIDE LOADING. All WLL ratings are based upon usual environmental condition and consideration must be given to unusual conditions such as extreme high heat or low temperatures, chemical solutions or vapors, prolonged immersion in salt water, etc. NEVER EXCEED THE WORKING LOAD LIMIT.

There are, however, other terms used in the industry which are interchangeable with the term WORKING LOAD LIMIT. These are WLL, SWL, SAFE WORKING LOAD, RATED LOAD VALUE, RESULTING SAFE WORKING LOAD, and RATED CAPACITY.

PROOF TEST LOAD (PROOF LOAD)

The term “Proof Test” designated a quality control test applied to the product for the sole purpose of detecting defects in material or manufacture. The Proof Test Load (usually twice the Working Load Limit) is the load, which the product withstood without deformation when new and under laboratory test conditions. A constantly increasing force is applied in direct line to the product at a uniform rate of speed on a standard pull-testing machine. The Proof Test Load does not mean the Working Load Limit should ever be exceeded.

BREAKING STRENGTH / ULTIMATE STRENGTH

Do not use breaking strength as a criterion for service or design purposes. Refer to the Working Load Limit instead. Breaking Strength is the average force at which the product, in the condition it would leave the factory, has been found by representative testing to break, when a constantly increasing force is applied in direct line to the product at a uniform rate of speed on a standard pull testing machine. Proof testing to twice the Working Load Limit does not apply to hand-spliced slings. REMEMBER: Breaking Strengths, when published, were obtained under controlled laboratory conditions. Listing of the Breaking Strength does not mean the Working Load Limit should ever be exceeded.

DESIGN FACTOR (sometimes referred to as safety factor)

An industry term usually computed by dividing the catalog Breaking Strength by the Catalog Working Load Limit and generally expressed as a ratio. For example: 5 to 1.

SHOCK LOAD

A load resulting from rapid change of movement, such as impacting, jerking, or swinging of a static load. Sudden release of tension is another form of shock loading. Shock loads are generally significantly greater than static loads. Any shock loading must be considered when selecting the item for use in a system. AVOID SHOCK LOADS AS THEY MAY EXCEED THE WORKING LOAD LIMIT.