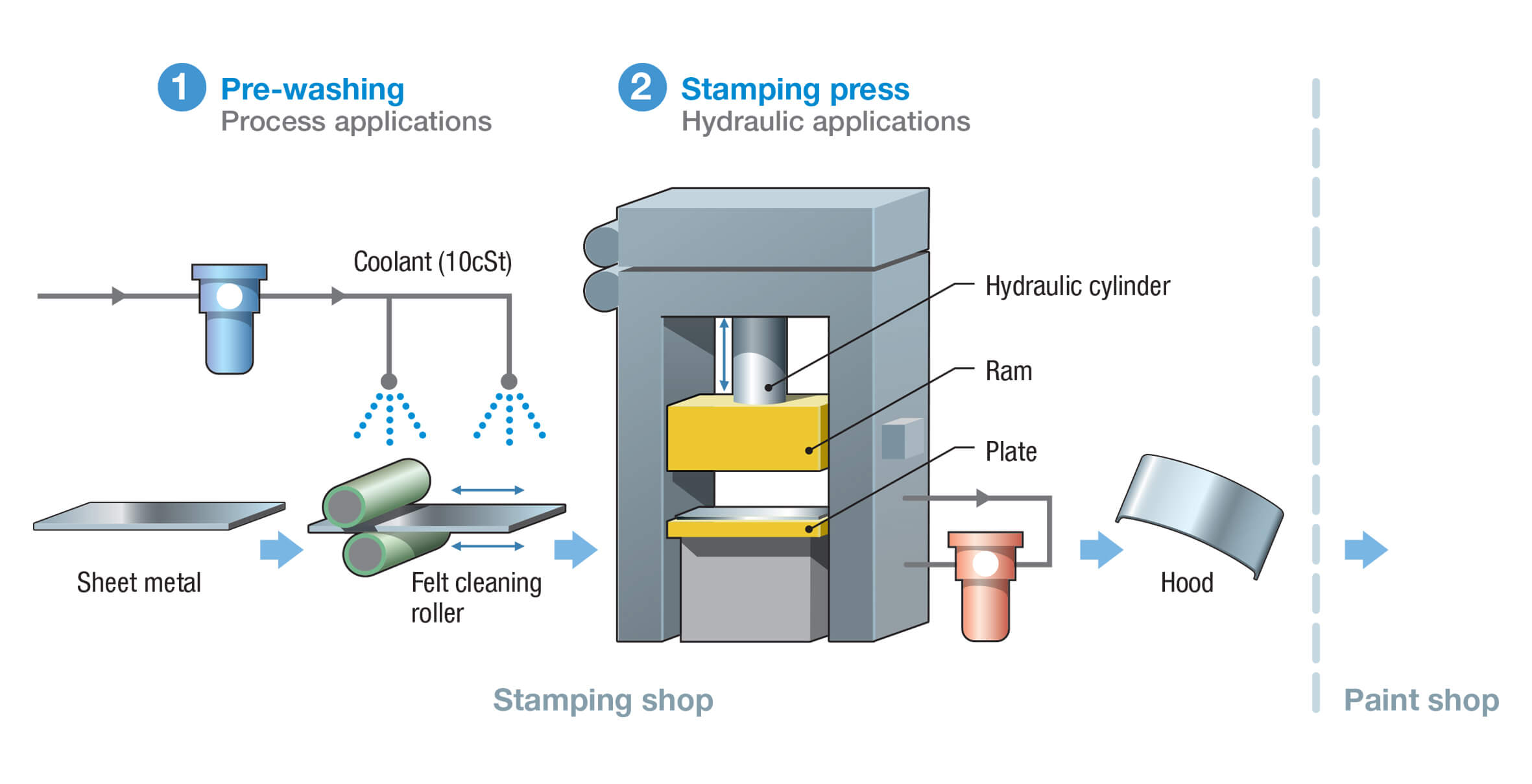

In manufacturing, “stamping” usually means sheet metal stamping machinery and manufacturing processes. What is sheet metal stamping? How does it work? Here are the basics of the process as well as how it can be used.

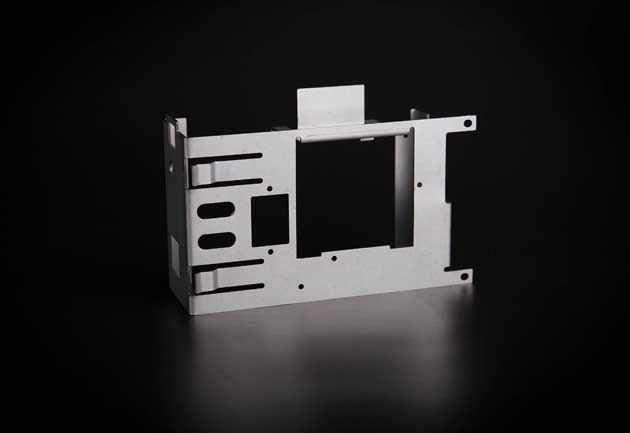

The definition of sheet metal stamping is that it’s a type of cold forming process, using extreme force or speed to alter the shape of a piece of metal. The work piece is sheet metal. However, metal stamping machines can be used for metal wires and other metal forms as well.

The basic operating theory of a metal stamping machine is very simple: you take a large tool and die, put it into a machine that can exert several tons of force very quickly, and use them to press metal objects into the shape you want.

There are several different processes that a sheet metal stamping machine can typically perform:

1.Flattening Metal. This can be done to either smooth out an object or render it thinner at one point for other purposes.

2.Piercing Metal. The tool and die from a sheet metal stamping machine can puncture all the way through a piece of metal. This creates openings that can be used to connect multiple work pieces.

3.Coining Metal. The tool and die of the sheet metal stamping machine can be used to press the sheet metal into a specific shape (such as a coin).

Because sheet metal stamping machines work on cold pieces of metal that haven’t been rendered malleable, they must rely on extreme force to get the job done. We have key equipment, includes stamping machine which exerts up to a extreme large force, CNC Bending machine, TRUMPF TRULASER (Germany) laser cutting machine, Automatic electric galvanizing line and others, build our a strong processing and assembly capacity.

According to customer’s requirement, we can provide CAD design and programming from material incoming to parts drawings. Since the ability to use computer aided design and a variety of special structures, our team is able to create high-quality products and provide sound service for customers throughout the whole process. Welcome your consulting!

By Katie