Understanding Material Toughness: From Impact Resistance to Fracture Mechanics

What is Toughness? In mechanical design and materials engineering, materials must not only possess sufficient strength under load

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

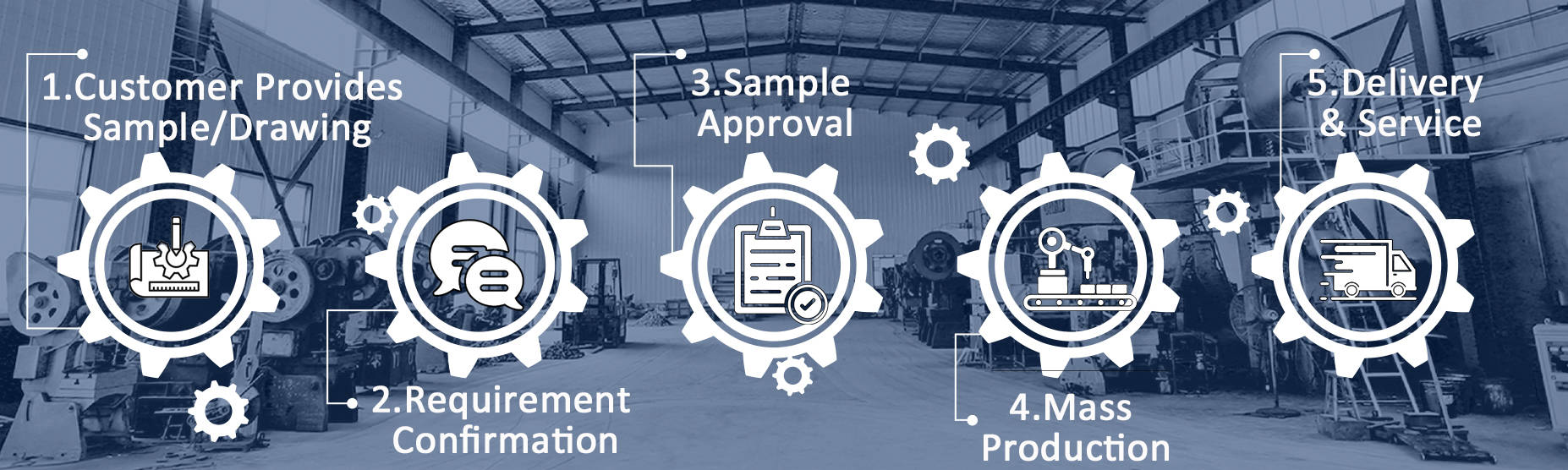

Over 20 years of industry experience, dedicated to delivering high-precision and highly durable products.

Dimensions, materials, and processes can all be tailored to your specific requirements.

Equipped with a CNAS-certified comprehensive laboratory and a complete quality control system.

Clear lead times for both sample development and mass production.

EMP has a CNAS-certified laboratory and a complete quality inspection process, ensuring consistency from samples to batches.

EMP has over 20 years of export experience and has professional designers for one-on-one communication to ensure zero errors in understanding the drawings, materials, and processes.

EMP clearly promises the sample-making cycle and mass production cycle, with detailed production scheduling plans.

EMP will sign confidentiality agreements with clients, and the company implements a classified management system for client drawings to ensure information security.

What is Toughness? In mechanical design and materials engineering, materials must not only possess sufficient strength under load

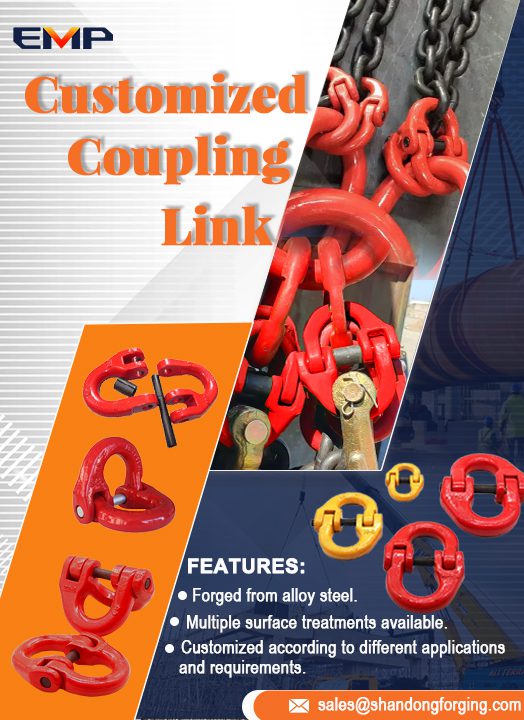

Our customized coupling links are engineered for heavy-duty and safety-critical applications, delivering reliable performance under demanding conditions. Key

When it comes to outdoor cooking, whether you’re camping in the wilderness, tailgating before the big game, or

In forging, there is an invisible yet deadly defect—folding.Folding occurs when metal flow is uneven, causing overlapping surfaces

In a world where mobility, safety, and fast deployment are becoming essential, the EMP Double-Winged House offers a

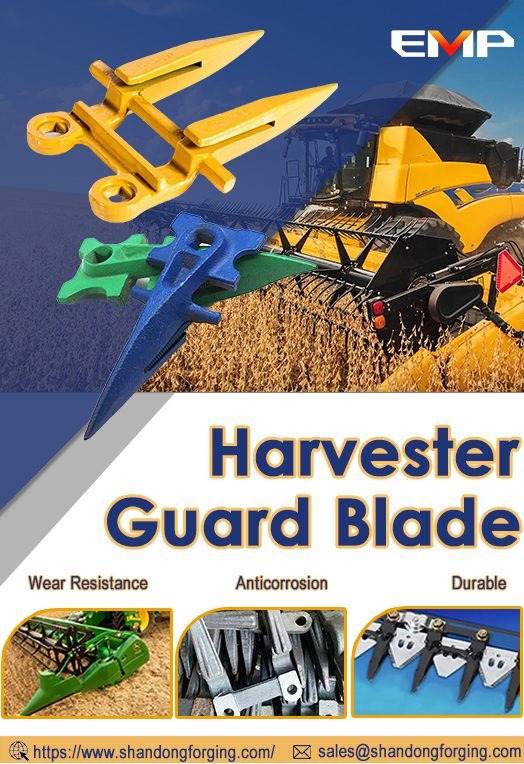

When the harvest season arrives, every machine part matters. The EMP Harvester Guard Blade is engineered to be

Min.trace width: | 2.5mil | Min.trace spacing | 2.5mil |

| Min.Vias: | 6mil(4mil laser drilling) | Max.layer | 48L |

Min.BGA spacing | 0.35mm | Max.BGA Pin | 3600pin |

| Max.high-speed signal | 40 GBPS | Fastest delivery time | 6 Hours/ Item |

HDI Highest layer | 22 L | HDI Highest layer | 14 L any layer HDI |