Understanding Material Toughness: From Impact Resistance to Fracture Mechanics

What is Toughness? In mechanical design and materials engineering, materials must not only possess sufficient strength under load

In the list of importers – 45 countries: Germany, Spain, Italy, Poland,

Portugal, Turkey, South Korea, Japan, etc.

EMP transforms concepts into practical and appealing product designs — ensuring both aesthetics and functionality.

EMP’s engineering team accelerates development with rapid prototyping, verifying performance and refining details before mass production.

EMP selects optimal materials and processes to maximize durability, efficiency, and cost-effectiveness — tailored to each project’s needs.

EMP conducts rigorous testing and provides compliance certifications to guarantee every product meets global quality standards.

EMP scales production with advanced facilities and delivers worldwide through reliable logistics networks.

Over two decades of experience serving international markets, ensuring smooth communication, compliance, and reliable delivery worldwide.

A skilled engineering and design team that transforms your ideas into practical, innovative, and market-ready solutions.

In-house testing capabilities with a CNAS-accredited lab, guaranteeing strict quality control and global standard compliance.

Comprehensive support at every stage — from concept design and prototyping to production, packaging, and international shipping.

Long-term cooperation with clients around the world, supporting diverse industries with reliable ODM solutions.

Over two decades of experience serving international markets, ensuring smooth communication, compliance, and reliable delivery worldwide.

A skilled engineering and design team that transforms your ideas into practical, innovative, and market-ready solutions.

In-house testing capabilities with a CNAS-accredited lab, guaranteeing strict quality control and global standard compliance.

Comprehensive support at every stage — from concept design and prototyping to production, packaging, and international shipping.

Long-term cooperation with clients around the world, supporting diverse industries with reliable ODM solutions.

EMP specializes in supplying high-strength, corrosion-resistant architectural metal parts suitable for various construction projects such as steel structures, curtain walls, and piping systems.

EMP specializes in supplying high-reliability, long-life core components for energy equipment, covering both traditional power and new energy fields.

EMP specializes in supplying high-precision, high-performance automotive parts for passenger cars, commercial vehicles and new energy vehicles.

EMP specializes in supplying high-strength, wear-resistant core components for construction machinery, suitable for heavy equipment such as excavators, loaders, cranes, etc.

EMP specializes in supplying highly corrosion-resistant and highly reliable ship-specific parts to meet the stringent requirements of ocean-going and inland vessels.

EMP specializes in supplying highly wear-resistant and impact-resistant mining equipment parts, suitable for harsh working conditions such as crushing, drilling, and transportation.

Custom casting service is the production of specific parts based on the customer’s design requirements, using precision casting technology. It ensures that each component meets your specifications, whether it is the size, material, or performance.

Design drawings or CAD files.

Expected materials.

Desired size, shape, and tolerance requirements.

Any specific functional requirements or surface treatment requests.

EMP offers a range of casting materials, including:

Aluminum: Lightweight, corrosion-resistant, ideal for automotive and appliances.

Cast iron: Strong, suitable for engines and mechanical parts.

Copper alloys: Excellent conductivity, ideal for electrical devices.

We can also choose materials and alloys based on your specific needs.

EMP strictly follows the ISO 9001 quality management system for production and has a CNAS certified laboratory with a complete quality inspection process.

Yes, EMP’s engineering team can provide design support and technical consulting services. We can assist in optimizing your design to ensure the parts meet casting process requirements, and offer cost optimization suggestions.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

What is Toughness? In mechanical design and materials engineering, materials must not only possess sufficient strength under load

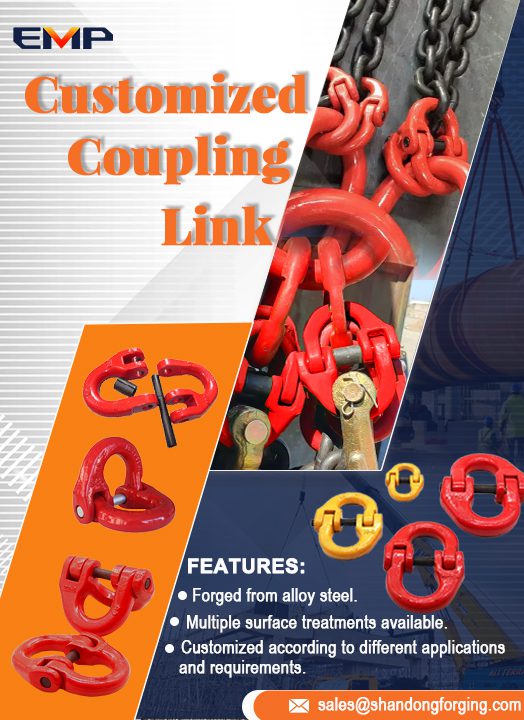

Our customized coupling links are engineered for heavy-duty and safety-critical applications, delivering reliable performance under demanding conditions. Key

When it comes to outdoor cooking, whether you’re camping in the wilderness, tailgating before the big game, or

In forging, there is an invisible yet deadly defect—folding.Folding occurs when metal flow is uneven, causing overlapping surfaces

In a world where mobility, safety, and fast deployment are becoming essential, the EMP Double-Winged House offers a

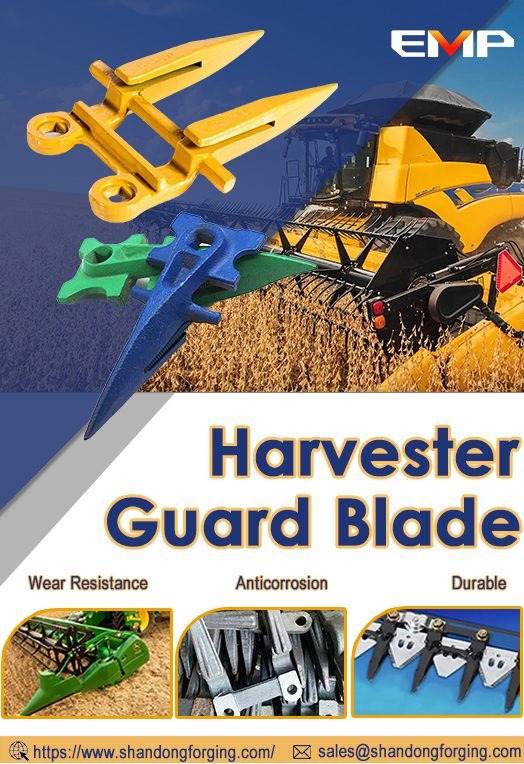

When the harvest season arrives, every machine part matters. The EMP Harvester Guard Blade is engineered to be