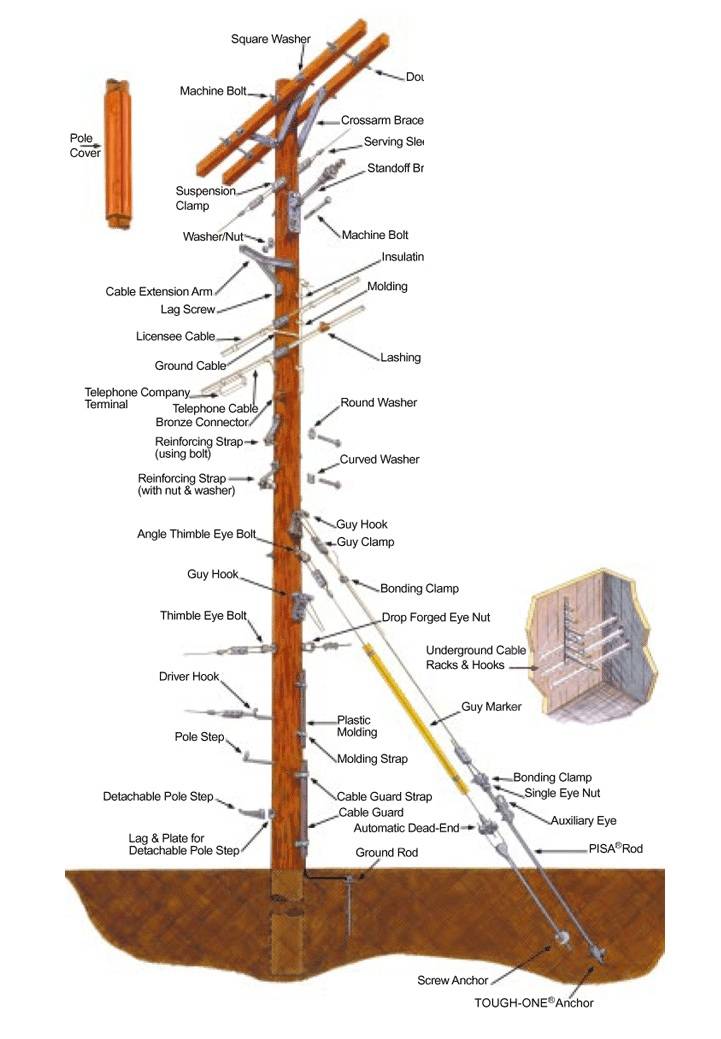

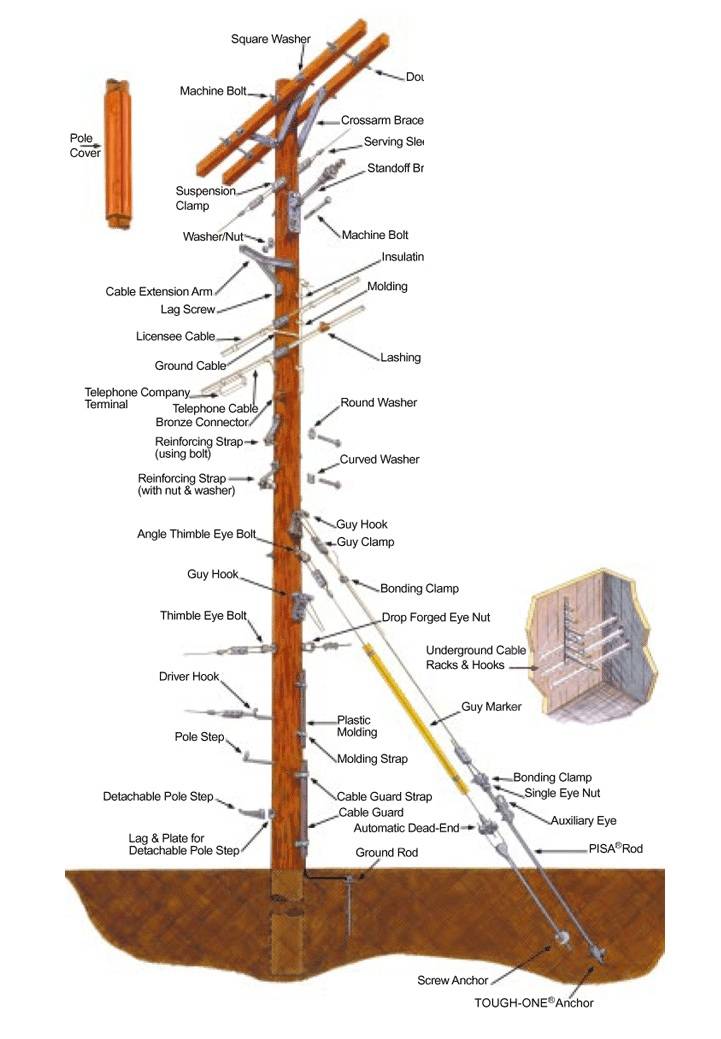

So necessarily, most of the pole line hardware is needful as a way of enhancing the safety of the power materials. In most instance, such hardware help to hold the various cables, insulators, transformers or many other elements in position.

So necessarily, most of the pole line hardware is needful as a way of enhancing the safety of the power materials. In most instance, such hardware help to hold the various cables, insulators, transformers or many other elements in position.